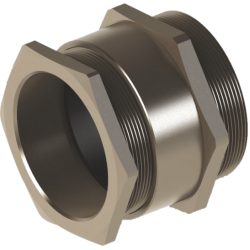

A2 METAL CABLE GLANDS FLAT TYPE BRASS

TECHNICAL DETAILS

Material

Cap nut: Brass with nickel plated

Sealing ring: EPDM

Gland body: Brass with nickel plated

O-ring: NBR

Connection thread: Metric (EN60423)/PG (DIN 40430)

Protection class: IP54

Temperature range: -20 °C + 100 °

-40 °C + 150 °C

Properties

Easy to assemble

High mechanical stability

Optimum strain relief

ÜRÜN AÇIKLAMASI GELECEK

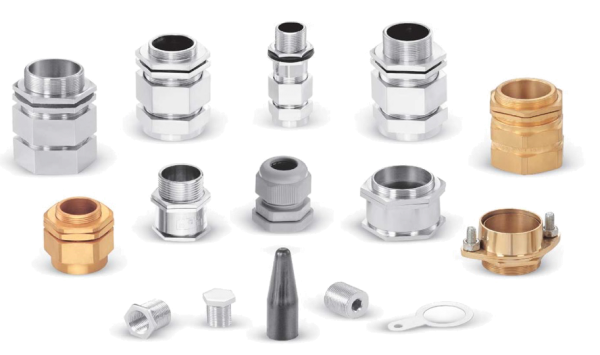

Flexible Conduit System Adaptors

Flexible Conduit System Adaptors

| ITEM CODE | SIZE |

| ZMMB-S-3/4” | 3/4” |

| ZMMB-S- 1” | 1” |

| ZMMB-S- 1-1/4” | 1-1/4” |

| ZMMB-S- 1-1/2” | 1-1/2” |

| ZMMB-S- 2” | 2” |

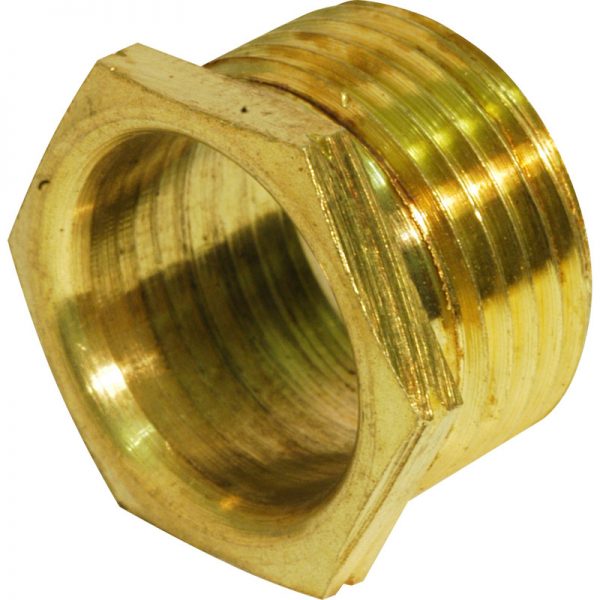

FITTINGS AND ACCESSORIES-BRASS FITTINGS-MALE BUSH – SHORT

Material: Brass

Finish: Self Colour

| ITEM CODE | SIZE |

| ZMMB-L-3/4” | 3/4” |

| ZMMB-L- 1” | 1” |

| ZMMB-L- 1-1/4” | 1-1/4” |

| ZMMB-L- 1-1/2” | 1-1/2” |

| ZMMB-L- 2” | 2” |

FITTINGS AND ACCESSORIES-BRASS FITTINGS-MALE BUSH – LONG

Material: Brass

Finish: Self Colour

| ITEM CODE | SIZE |

| ZMFB-1-3/4” | 3/4” |

| ZMFB-1- 1” | 1” |

| ZMFB-1- 1-1/4” | 1-1/4” |

| ZMFB-1- 1-1/2” | 1-1/2” |

| ZMFB-1- 2” | 2” |

FITTINGS AND ACCESSORIES-BRASS FITTINGS-FEMALE BUSH

Material: Brass

Finish: Self Colour

| AG Thread |

Code | H mm |

GL mm |

mm | mm |

| M 12 x 1,5 | ZMDOMR 01 | 16 | 5 | 14 | 3,5 – 6 |

| M 16 x 1,5 | ZMDOMR 02 | 17 | 5 | 18 | 4,5 – 7 |

| M 20 x 1,5 | ZMDOMR 03 | 19 | 6 | 22 | 9 – 12 |

| M 25 x 1,5 | ZMDOMR 04 | 20,5 | 7 | 27 | 11 – 14 |

| M 32 x 1,5 | ZMDOMR 05 | 22,5 | 8 | 34 | 14 – 18 |

| M 40 x 1,5 | ZMDOMR 06 | 25 | 8 | 45 | 18 – 25 |

| M 50 x 1,5 | ZMDOMR 07 | 30 | 9 | 55 | 25 – 32 |

| M 63 x 1,5 | ZMDOMR 08 | 47 | 15 | 70 | 38 – 44 |

| M 63 x 1,5 | ZMDOMR 09 | 47 | 15 | 70 | 40 – 49 |

| PG 7 | ZMDOPR 01 | 16 | 5 | 14 | 3,5 – 6 |

| PG 9 | ZMDOPR 02 | 17 | 6 | 17 | 4,5 – 7 |

| PG 11 | ZMDOPR 03 | 18 | 6 | 20 | 6 – 9 |

| PG 13,5 | ZMDOPR 04 | 19 | 6,5 | 22 | 9 – 12 |

| PG 16 | ZMDOPR 05 | 20,5 | 6,5 | 24 | 11 – 14 |

| PG 21 | ZMDOPR 06 | 22,5 | 7 | 30 | 14 – 18 |

| PG 29 | ZMDOPR 07 | 25 | 8 | 40 | 18 – 25 |

| PG 36 | ZMDOPR 08 | 30 | 8 | 50 | 25 – 32 |

| PG 42 | ZMDOPR 09 | 34 | 9 | 60 | 30 – 38 |

| PG 48 | ZMDOPR 10 | 47 | 15 | 70 | 38 – 44 |

| PG 48 | ZMDOPR 11 | 47 | 15 | 70 | 40 – 49 |

Metal Cable Glands

ÜRÜN AÇIKLAMASI GELECEK

METAL CABLE GLANDS SPIRAL TYPE BRASS

TECHNICAL DETAILS

Material

Cap nut: Brass wih nickel plated

Spiral top: Stainless steel (1.4310/AISI302)

Clamping insert: Polyamide PA6 V2

Sealing ring: TPV

Gland body: Brass with nickel plated

O-ring: NBR

Connection thread: Metric(EN60423)/PG (DIN 40430)

Protection class: IP68

Temperature range: -20 °C + 100 °C

-40 °C + 150 °C

Properties

With spiral top for bend protection

For highly movable flexible cables

Easy to assemble

High strain relief

| AG Thread |

Code | H mm |

GL mm |

d mm |

B mm |

C mm |

mm |

| M 12 x 1,5 | ZMSTCG 01 | 55 | 6 | 6,8 | 14 | 14 | 3 – 6,5 |

| M 16 x 1,5 | ZMSTCG 02 | 66 | 7 | 8,4 | 18 | 18 | 4 – 8 |

| M 20 x 1,5 | ZMSTCG 03 | 88 | 8 | 12,3 | 22 | 22 | 6 – 12 |

| M 25 x 1,5 | ZMSTCG 04 | 98 | 8 | 14,3 | 27 | 27 | 10 – 14 |

| M 32 x 1,5 | ZMSTCG 05 | 111 | 9 | 18,4 | 34 | 34 | 13 – 18 |

LONG METRIC SPIRAL CABLE GLANDS

| M 12 x 1,5 | ZMSTCGL 01 | 55 | 12 | 6,8 | 14 | 14 | 3 – 6,5 |

| M 16 x 1,5 | ZMSTCGL 02 | 66 | 12 | 8,4 | 18 | 17 | 4 – 8 |

| M 20 x 1,5 | ZMSTCGL 03 | 88 | 12 | 12,3 | 22 | 22 | 6 – 12 |

| M 25 x 1,5 | ZMSTCGL 04 | 98 | 12 | 14,3 | 27 | 24 | 10 – 14 |

| M 32 x 1,5 | ZMSTCGL 05 | 111 | 14 | 18,4 | 34 | 30 | 13 – 18 |

| PG 7 | ZSTPG 01 | 55 | 6 | 6,8 | 14 | 3 – 6,5 | |

| PG 9 | ZSTPG 02 | 66 | 6 | 8,4 | 17 | 4 – 8 | |

| PG 11 | ZSTPG 03 | 77 | 6 | 10,3 | 20 | 5 – 10 | |

| PG 13,5 | ZSTPG 04 | 88 | 6,5 | 12,3 | 22 | 6 – 12 | |

| PG 16 | ZSTPG 05 | 98 | 6,5 | 14,3 | 24 | 10 – 14 | |

| PG 21 | ZSTPG 06 | 111 | 7 | 18,4 | 30 | 13 – 18 |

LONG PG SPIRAL CABLE GLANDS

| PG 7 | ZSTPGL 01 | 55 | 10 | 6,8 | 14 | 3 – 6,5 |

| PG 9 | ZSTPGL 02 | 66 | 10 | 8,4 | 17 | 4 – 8 |

| PG 11 | ZSTPGL 03 | 77 | 10 | 10,3 | 20 | 5 – 10 |

| PG 13,5 | ZSTPGL 04 | 88 | 10 | 12,3 | 22 | 6 – 12 |

| PG 16 | ZSTPGL 05 | 98 | 10 | 14,3 | 24 | 10 – 14 |

| PG 21 | ZSTPGL 06 | 111 | 12 | 18,4 | 30 | 13 – 18 |

METAL CABLE GLANDS WITH TRACTION RELIEF BRASS

TECHNICAL DETAILS

Material

Cap nut: Brass with nickel plated

Sealing ring: TPV

Gland body: Brass with nickel plated

O-ring: NBR

Connection thread: Metric (EN60423)/ PG (DIN 40430)

Protection class: IP55

Temperature range: -20 °C + 100 °C

-40 °C + 150 °C

Properties

High strain relief

High mechanical stability

Building sites

Plant engineering

Electric motor manufacturing

| AG Thread |

Code | H mm |

GL mm |

mm | mm |

| M 12 x 1,5 | ZMKMR 01 | 22 | 5 | 14 | 3,5 – 6 |

| M 16 x 1,5 | ZMKMR 02 | 25 | 5 | 18 | 4,5 – 7 |

| M 20 x 1,5 | ZMKMR 03 | 26,5 | 6 | 22 | 9 – 12 |

| M 25 x 1,5 | ZMKMR 04 | 32 | 7 | 27 | 11 – 14 |

| M 32 x 1,5 | ZMKMR 05 | 35 | 8 | 34 | 14 – 18 |

| M 40 x 1,5 | ZMKMR 06 | 41 | 8 | 45 | 18 – 25 |

| M 50 x 1,5 | ZMKMR 07 | 44 | 9 | 55 | 25 – 32 |

| M 63 x 1,5 | ZMKMR 08 | 59 | 15 | 70 | 38 – 44 |

| M 63 x 1,5 | ZMKMR 09 | 59 | 15 | 70 | 40 – 49 |

| PG 7 | ZMKPR 01 | 22 | 5 | 14 | 3,5 – 6 |

| PG 9 | ZMKPR 02 | 25 | 6 | 17 | 4,5 – 7 |

| PG 11 | ZMKPR 03 | 26 | 6 | 20 | 6 – 9 |

| PG 13,5 | ZMKPR 04 | 26,5 | 6,5 | 22 | 9 – 12 |

| PG 16 | ZMKPR 05 | 28 | 6,5 | 24 | 11 – 14 |

| PG 21 | ZMKPR 06 | 32 | 7 | 30 | 14 – 18 |

| PG 29 | ZMKPR 07 | 35 | 8 | 40 | 18 – 25 |

| PG 36 | ZMKPR 08 | 41 | 8 | 50 | 25 – 32 |

| PG 42 | ZMKPR 09 | 44 | 9 | 60 | 30 – 38 |

| PG 48 | ZMKPR 10 | 59 | 15 | 70 | 38 – 44 |

| PG 48 | ZMKPR 11 | 59 | 15 | 70 | 40 – 49 |

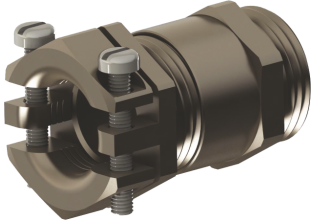

UNARMOURED CABLE GLANDS STEX SPIRAL TYPE

TECHNICAL DETAILS

Type: STex spiral type cable gland

Protection code: II 2G Ex db IIC Gb/II 2G Ex eb II Gb I M2 Ex db I Mb

I M2 Ex eb I Mb Ex tb IIIC Db

Certificate: IEP 16 ATEX 0436U

Material: MS58 Brass with or without nickel plated

Stainless steel (AISI303 / 316L / Aluminium

Spiral part: Stainless steel (1.4310/AISI302)

Standards: EN 60079-0:2012, 60079-7:2007,

60079-31:2009

Protection class: IP66 / 68

Temperature: 30 °C +120 °C NBR

: -40 °C +100 °C NEOPRENE

: -60 °C +180 °C SILICONE

: -30 °C +100 °C TPE/V

Application area: ZONE1, ZONE2, ZONE21, ZONE22,

Gas Group IIA. IIB, IIC

Cable type: Unarmoured

| Product Size | Code | Standard AG | Spiral Diameter (d) |

H mm |

Exd GL mm | Exe GL mm |

B mm |

C mm |

mm | ||||

| 12 | ZSTexXX/12/X | M 12 x 1,5 | 6,8 | 55 | 15 | 6 | 14 | 14 | 3 – 6,5 | ||||

| 16 | ZSTexXX/16/X | M 16 x 1,5 | 8,2 | 66 | 15 | 7 | 18 | 17 | 4 – 8 | ||||

| 20 | ZSTexXX/20/X | M 20 x 1,5 | 12,3 | 88 | 15 | 8 | 22 | 22 | 6 – 12 | ||||

| 25 | ZSTexXX/25/X | M 25 x 1,5 | 14,3 | 98 | 15 | 8 | 27 | 24 | 10 – 14 | ||||

| 32 | ZSTexXX/32/X | M 32 x 1,5 | 18,4 | 111 | 15 | 9 | 34 | 30 | 13 – 18 | ||||

| 12 | ZSTexXX/12/X | PG 7 | 6,8 | 55 | 15 | 6 | 14 | 3 – 6,5 | |||||

| 16 | ZSTexXX/16/X | PG 9 | 8,2 | 66 | 15 | 6 | 17 | 4 – 8 | |||||

| 16 | ZSTexXX/16/X | PG 11 | 10,3 | 77 | 15 | 6 | 20 | 5 – 10 | |||||

| 20 | ZSTexXX/20/X | PG 13,5 | 12,3 | 88 | 15 | 6,5 | 22 | 6 – 12 | |||||

| 25 | ZSTexXX/25/X | PG 16 | 14,3 | 98 | 15 | 6,5 | 24 | 10 – 14 | |||||

| 32 | ZSTexXX/32/X | PG 21 | 18,4 | 111 | 15 | 7 | 30 13 – 18 | ||||||

| 12 | ZSTexXX/12/X | NPT 1/4″ | 6,8 | 55 | 15 | – | 14 | 14 | 3 – 6,5 | ||||

| 16 | ZSTexXX/16/X | NPT 3/8″ | 8,2 | 66 | 15 | – | 18 | 17 | 4 – 8 | ||||

| 16 | ZSTexXX/16/X | NPT 1/2″ | 10,3 | 77 | 15 | – | 20 | 20 | 5 – 10 | ||||

| 20 | ZSTexXX/20/X | NPT 1/2″ | 12,3 | 88 | 15 | – | 22 | 22 | 6 – 12 | ||||

| 25 | ZSTexXX/25/X | NPT 3/4″ | 14,3 | 98 | 15 | – | 27 | 24 | 10 – 14 | ||||

| 32 | ZSTexXX/32/X | NPT 1″ | 18,4 | 111 | 15 | – | 34 | 30 | 13 – 18 | ||||

| NPT | & GAS | THREAD | |||||||||||

| 12 | STexXX/12/X | GAS 1/4″ | 6,8 | 55 | 15 | – | 14 | 14 | 3 – 6,5 | ||||

| 16 | ZSTexXX/16/X | GAS 3/8″ | 8,2 | 66 | 15 | – | 18 | 17 | 4 – 8 | ||||

| 16 | ZSTexXX/16/X | GAS 3/8″ | 10,3 | 77 | 15 | – | 20 | 20 | 5 – 10 | ||||

| 20 | ZSTexXX/20/X | GAS 1/2″ | 12,3 | 88 | 15 | – | 22 | 22 | 6 – 12 | ||||

| 25 | ZSTexXX/25/X | GAS 3/4″ | 14,3 | 98 | 15 | – | 27 | 24 | 10 – 14 | ||||

| 32 | ZSTexXX/32/X | GAS 1″ | 18,4 | 111 | 15 | 34 30 13 – 18 | |||||||

* Pls add “ E ” to the code if required Exe protection.